The Art of Handmade

A ceramic design often starts as a simple sketch on a piece of paper and goes through a lengthy creative process before being selected for production. Once the basic clay shapes are made, every piece is fired three times, in enormous kilns, before any decoration is added.

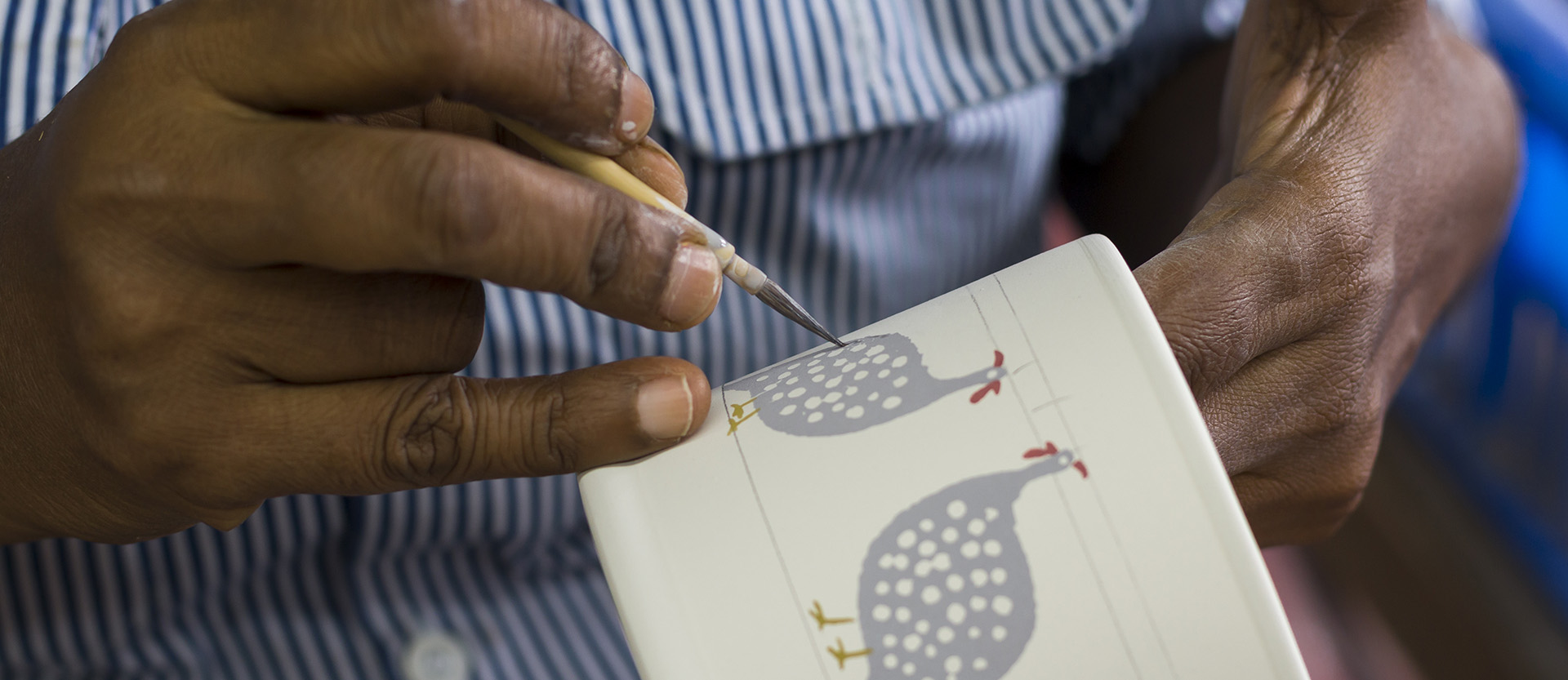

Each design is delicately hand-decorated; sponges are cut out by hand before being carefully positioned on to the piece, the finer details are then applied freehand by brush. The finishing touch is the artists initials on the base, before a fourth and final firing. The end result is a beautiful yet durable ceramics collection, each one a little work of art and robust enough to be enjoyed every single day.